Published: January 2002

|

|

When a twin-aisle airplane is used for short-flight operations, brakes may heat unevenly on each landing, with the difference in temperatures becoming more pronounced with repeated landings. At the gate, the brake temperature display may indicate that some brakes are hotter than others. Temperatures may continue to climb until the brake temperature light illuminates or an alert displays. Understanding the causes of uneven brake heating and the meaning of the brake temperature indication can help flight crews minimise possible departure delays. This article explains the following:

- Factors that lead to uneven brake heating.

- Interpretation of the brake temperature indication.

- Flight crew action that can minimise uneven brake heating.

1. FACTORS THAT LEAD TO UNEVEN BRAKE HEATING

Slowing an airplane requires the dissipation of kinetic energy. Kinetic energy that is not absorbed by the thrust reversers and speed brakes is converted to heat energy by the wheel brakes. The weight and speed of the airplane during landing and taxiing determine how much energy the brake friction (i.e., heat stack) material absorbs.

Factors that lead to uneven brake heating include variation in brake wear, inadvertent asymmetrical braking, and wind conditions.

Variation in brake wear.

Brakes that are approaching wear limits can become as much as 30 percent hotter than unworn brakes. This variation in temperature simply reflects the difference in the amount of brake friction material.

Inadvertent asymmetrical braking.

Temperature differences between brakes on the left and right gears often arise from inadvertent asymmetrical braking. When the brakes and rudder pedals are used concurrently to maintain heading and keep speed under control, it is easy for flight crews to inadvertently apply asymmetrical braking inputs that — unknown to them — are being compensated for by the rudder. When the pedal brakes are applied lightly during taxi braking and landings, temperature differences among the brakes on each landing gear can increase quickly.

Wind conditions.

Brakes cool by convection, and even a moderate breeze can result in temperature differences among brakes that are exposed to wind and those that are sheltered from it.

Given these factors, it is important to remember that temperature differences between the two sides of an airplane do not necessarily mean that a problem exists with the braking system or the brake temperature monitor.

2. INTERPRETATION OF THE BRAKE TEMPERATURE INDICATION

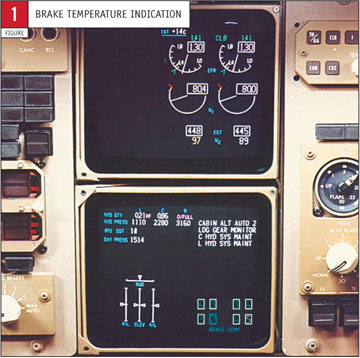

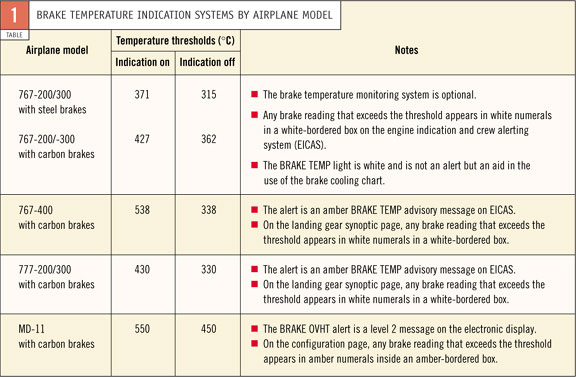

The BRAKE TEMP light illuminates (or a BRAKE OVHT alert displays) when the temperature of a brake rises above a predetermined level and turns off when all the brakes have cooled to a certain level (figure 1). These levels vary by airplane model and type of brake (table 1).

The BRAKE TEMP light and BRAKE OVHT alert indicate that the radiated and conducted heat from the brake may cause a wheel fuse plug to melt to release air pressure from the tire safely. Whether or not the fuse plug actually melts depends on how far the threshold setting for the brake temperature indication has been exceeded (i.e., the higher the reading on the brake temperature display, the greater the likelihood of the fuse plug melting). The aircraft maintenance manual describes the procedures for checking for deflated tires and hydraulic leaks. (Hydraulic leaks can result from overheated brake piston seals after a BRAKE TEMP or BRAKE OVHT indication has occurred.) If no anomalies are found, the maintenance crew may clear the airplane for dispatch.

Brake temperatures tend to increase from one landing to the next during short-flight operations. On the first landing of the day, the brakes are relatively cool because of the length of time since the last significant energy input. When the airplane leaves the gate for the next flight, however, the brakes will still be warm from the previous landing, and more energy will accumulate from braking during the taxi out. The brakes will not cool completely on a short flight, and during the next landing, the same braking effort will produce higher peak temperatures. The temperature differences between new and worn brakes also will increase with repeated landings. Because of these factors, a BRAKE TEMP or BRAKE OVHT indication will more likely occur toward the end of the day and especially in hot weather.

If landing conditions for an airplane exceed certain maximums listed in the airplane flight manual (AFM) quick-turnaround charts, departure may be delayed for a prescribed period of time to let the brakes cool. The airplane may be allowed to depart before the end of that period if the true brake temperatures, as shown by the brake temperature indication, are lower than those predicted in the AFM.

3. FLIGHT CREW ACTION THAT CAN MINIMISE UNEVEN BRAKE HEATING

How the flight crew uses the brake system in conjunction with reverse thrust and the spoilers during landing significantly affects the amount of energy transferred to the brake stacks. Flight crews can use several techniques to arrive at the airport gate with cooler brakes.

On long runways, aerodynamic drag and thrust reversers may provide plenty of deceleration at high speed, and braking can be delayed until taxi speeds are reached. If autobrakes are used, the flight crew should choose the lowest deceleration setting commensurate with the available field length; landing long and turning off short should be avoided. Brake energy balance is improved when the autobrakes are used all the way down to taxi speeds because the same hydraulic pressure is applied to every brake.

On the taxiway, moderate brake applications followed by full pedal release keep the brakes cooler than would a steady application of light brake pressure (i.e., riding the brakes). Using this technique makes it less likely that the BRAKE TEMP or BRAKE OVHT indication will come on because of one disproportionately hot brake. (It should be noted that minimising the number of brake applications can reduce wear on carbon brakes.)

SummaryDuring short-flight operations, flight crews can take steps to pass on a cooler set of brakes to the next crew. Crews can carefully manage brake energy during landing and taxiing by

If the BRAKE TEMP or BRAKE OVHT indication still occurs, published maintenance procedures should be performed. |

Editor's note: For related information, refer to the Aug. 1, 1990, issue of the Boeing Flight Operations Review and the latest revision of the Boeing Flight Crew Training Manual.

BOB MACKNESS

ASSOCIATE TECHNICAL FELLOW

MECHANICAL/HYDRAULIC SYSTEMS

BOEING COMMERCIAL AIRPLANES

| Top of page | Boeing Home | Boeing Commercial | Contact Aero |

Aero Copyright © 2003 The Boeing Company. All rights reserved.