Published: July 2002

|

|

As part of its effort to ensure the continued airworthiness of aging airplanes (i.e., airplanes built to type designs that are more than 20 years old), the U.S. Federal Aviation Administration (FAA) formed a fact-finding committee in 1998 to evaluate the airplane systems of the aging fleet and propose enhancements to current procedures. The Aging Transport Systems Rule-making Advisory Committee (ATSRAC), which is composed of representatives from various segments of the aviation industry, is focusing its investigation on airplane wiring. (See "Aging Airplane Systems Investigation," Aero no. 7, July 1999.) The committee completed its initial tasks in January 2001 and is continuing with plans to implement its recommendations. This article discusses

- ATSRAC findings and recommendations.

- Implementation of ATSRAC recommendations.

- FAA actions.

- Enhanced Airworthiness Program for Airplane Systems.

- Boeing support.

1. ATSRAC Findings and Recommendations

The initial ATSRAC investigation of aging airplane wiring studied five factors: fleet condition, fleet service history, maintenance criteria, standard practices for wiring, and inspection and repair training. A team of ATSRAC members and industry representatives was assigned to evaluate each parameter. The teams conducted analyses, made conclusions, and recommended follow-up actions, which the ATSRAC then reviewed, approved, and provided to the FAA.

Although none of the teams identified any issue related to the immediate safety of the aging fleet, they did suggest enhancements to existing design, maintenance, and operational procedures for the continued airworthiness of all airplanes.

Fleet condition.

One team reviewed the condition of the aging fleet by conducting a non-intrusive evaluation of the wiring on 81 in-service airplanes and a detailed, intrusive inspection of the wiring removed from six recently retired airline airplanes.

The team found that wiring degradation primarily is not related to the age of the airplane (i.e., the time since manufacture), the environment in which the airplane operates, or the type of wiring. Rather, wiring degradation is influenced significantly by the maintenance and modification performed throughout the life of the airplane. The team also determined that a general visual inspection of the wiring installed on airplanes, which typically is conducted from a distance of a few feet, cannot adequately assess the condition of the wiring. Specific recommendations included an increased emphasis on the periodic removal of accumulated contaminants and clarification of the requirements regarding the spatial separation of wiring for critical airplane systems.

Fleet service history.

A second team reviewed all existing service information applicable to the older airplanes under study. Of the thousands of wiring-related service documents (e.g., service bulletins, service letters, all-operator letters, in-service activity reports) reviewed, 29 service bulletins contained airplane modifications important enough to justify upgrading the service bulletins to alert status. (Boeing releases alert service bulletins to address issues of safety over the life of the fleet.) The FAA has released 26 airworthiness directives (AD) and proposed one AD that mandate incorporation of the modifications.

Maintenance criteria.

A third team evaluated the recommended scheduled maintenance activities for older airplanes. Most modern commercial airplanes are delivered with a recommended maintenance plan based on an airplane zonal analysis using the Maintenance Steering Group Level 3 (MSG-3) evaluation process. However, the MSG-3 and previous evaluation processes did not consider the airplane wiring as a specific system. The typical result was that airplane wiring was examined visually when a maintenance technician was in the general area for other reasons.

The team concluded that an enhanced maintenance analysis process was needed to specifically evaluate airplane wiring. This enhanced zonal analysis procedure (EZAP) can be accomplished on all airplanes regardless of whether they have been evaluated previously using the MSG-3 process.

ENHANCED ZONAL ANALYSIS PROCEDURE

The enhanced zonal analysis procedure (EZAP) is a method of analysing airplane zones, with an emphasis on wiring systems. Developed by an industry team chartered by the Aging Transport Systems Rulemaking Advisory Committee, the EZAP consists of four basic steps:

- For a given airplane zone, the analyst identifies all systems (including wiring systems), structures, components, and any present or possible combustible materials (e.g., fuel vapours, dust or lint particles, contamination).

- The analyst determines whether the zone contains both wiring and combustible materials.

- If the zone contains both wiring and combustible materials, the analyst will determine whether it is possible to define an applicable and effective task with an appropriate maintenance interval to remove or minimise the build-up of combustible materials in the zone (e.g., a cleaning task to remove the dust or lint particles).

- If the zone contains both wiring and combustible materials, the analyst also will determine whether it is possible to define an applicable and effective task for inspecting the zone. To accomplish this, the analyst must determine the appropriate level of inspection (e.g., a general visual inspection [GVI] of the entire zone, a GVI of specific wiring within the zone, or a detailed inspection of specific wiring in the zone) and associated maintenance intervals. Factors to consider when determining the level of inspection and maintenance intervals include the types of wire in the zones, the size and density of the zone, the potential effects of a fire within a zone, environmental effects, and the likelihood of accidental damage.

For effective application of the EZAP, it is highly recommended that the analyst have direct access to the airplane. This allows the analyst to determine what is installed in the zone and understand other key features of the zone (e.g., size, density, environmental effects).

The EZAP is well suited to maintenance programs with a dedicated zonal inspection program because any GVIs of an entire zone resulting from the EZAP may be consolidated into an existing zonal task. For maintenance programs without a dedicated zonal inspection program, the EZAP may result in additional tasks in the systems and power plant maintenance program.

Boeing has applied the EZAP as part of an effort to update the 727 maintenance program to the latest Maintenance Steering Group Level 3 standards. Boeing will continue to use the EZAP on all in- and out-of-production airplanes. Any resulting enhanced wiring inspections will be referenced in revisions to associated maintenance planning documents.

For further details of the EZAP, please refer to the following documentation:

- Aging Transport Systems Rulemaking Advisory Committee, Task 3, Final Report,

http://www.mitrecaasd.org/atsrac/final_reports/Task_3_Final.pdf. - Operator/Manufacturer Scheduled Maintenance Development, Revision 2001, Air Transport Association (ATA) Maintenance Steering Group Level 3, ATA of America, 1301 Pennsylvania Ave. NW, Suite 1100, Washington, DC 20004-1707, USA.

Standard practices for wiring.

Another team evaluated the documentation concerning wiring repair and maintenance and determined that the information used to inspect, repair, and replace airplane wiring could be improved and made easier to use. The team recommended that all airplane manufacturers adopt a common document format and include the same types of information in new documents so that technicians and engineers can easily use documents from different manufacturers. The team also recommended that existing documents be updated to reflect the revised format and content.

Inspection and repair training.

The fifth team reviewed available programs for training personnel with access to wiring and electrical systems. The team found a need for a training program specific to wiring to ensure that all aviation personnel who are in contact with the airplane are aware of the importance of airplane wiring. The team recommended a training curriculum that is standardised, with content customised to operators' specific airplane models.

2. Implementation of ATSRAC Recommendations

The teams recommended enhancements to maintenance programs, training programs, airplane documentation, and future airplane design. However, the level of detail and the methods of implementing these enhancements needed further development.

In January 2001, the FAA re-chartered the ATSRAC to provide more details on the recommendations and develop implementation plans. Specifically, the FAA asked the ATSRAC to accomplish four tasks by January 2003:

- Review and consolidate the federal regulations used to certify airplane wiring systems.

- Standardise the format and content of wiring standard-practices documents.

- Develop the content and implementation plan for an industry-wide common training program.

- Develop an enhanced zonal maintenance plan.

To accomplish these tasks, the ATSRAC formed four new teams, each co-chaired by industry representatives under the authority of the FAA and the European Joint Aviation Authorities. In addition to completing its specified task, each team was asked to produce guidance material in the form of draft advisory circulars (AC) and recommend specific terminology for use in future regulatory mandates.

3. FAA Actions

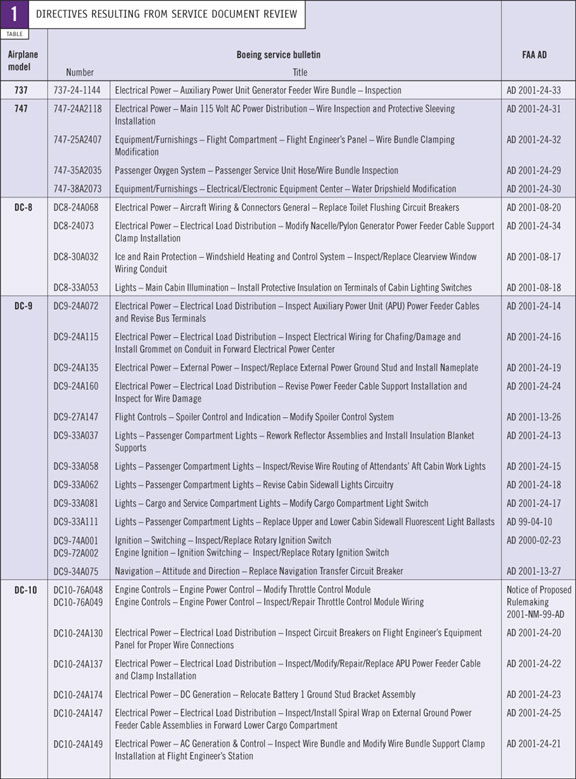

The FAA already has taken regulatory action to increase the margin of safety of older airplane models. These actions include issuing ADs regarding airplane modifications (table 1), developing a training program about airplane wiring systems, forming a policy statement on the certification of wiring systems, releasing bulletins on operation specifications and the principal maintenance inspector handbook, and improving rules and communication with worldwide regulatory authorities on service difficulty reports.

The FAA's long-term plans are to

- Implement the remaining four ATSRAC tasks.

- Change maintenance and training requirements under Part 121 of the Federal Aviation Regulations (FAR).

- Release related ACs and operation specifications.

- Enhance airplane design requirements as appropriate.

- Issue requirements and guidelines for the installation of arc-fault circuit breakers that are under development.

- Establish wire performance requirements.

- Develop an automated system for reporting service difficulties.

- Conduct ongoing research and development of maintenance equipment used in the assessment

of airplane wiring.

Institutionalising the ATSRAC results and recommendations will require all holders of type certificates and supplemental type certificates to change existing instructions for continued airworthiness. These requirements are expected to apply to all FAR Part 91, 121, 125, 129, and possibly 135 operators. In addition, changes to Part 25 will combine existing wiring design and certification requirements and include any new requirements identified by the ATSRAC. These changes will apply to all new type certificate and supplemental type certificate applications.

The FAA plans to release a special federal aviation regulation (SFAR), based on ATSRAC recommendations, which will mandate the incorporation of an EZAP to enhance airplane maintenance programs. In addition, the FAA plans to update sections of the FARs for private, charter, and domestic commercial operators and foreign commercial operators operating in the United States. These operators will be required to update their maintenance and training documentation to include the noted enhancements. In addition to the SFAR and changes to FAR Parts 91, 121, 125, and 129, related ACs will provide guidance on an acceptable means of compliance.

The FAA expects to begin developing the SFAR changes, the FAR changes, and the accompanying ACs and other guidance material during fourth-quarter 2002. The ATSRAC will review these materials before they are placed on the public docket to help ensure that mandated actions are readily implemented in the fleet. All changes are subject to public review under the Notice of Proposed Rulemaking procedures. Regulation changes, AC releases, and the issuance of operations specifications are expected to continue through 2004.

4. Enhanced Airworthiness Program for Airplane Systems

The ATSRAC efforts are part of an overarching plan developed by the FAA known as the Enhanced Airworthiness Program for Airplane Systems (EAPAS). The EAPAS outlines the results and recommendations of the ATSRAC and other fact-finding groups and explains how this knowledge will be applied throughout the aviation industry. Although the program has been designed to encourage voluntary compliance, the FAA's objective of institutionalising an enhanced and acceptable level of safety requires the use of mandatory requirements. The EAPAS organises this information and initiates both short-term and long-term implementation actions to enhance the safety of the entire domestic fleet. For this reason, the EAPAS omits specific reference to older airplanes. The program is intended to focus on all airplane systems, with mechanical systems to undergo detailed evaluation after wiring.

5. Boeing Support

Boeing supports the ATSRAC and EAPAS through active participation and the development of both guidance material and programs to comply with expected regulatory mandates.

-

Boeing has developed the EZAP based on the MSG-3 process for older Boeing airplane models. Boeing has applied the EZAP to the 727 and plans to apply it to all in- and out-of-production airplanes.

-

FlightSafety Boeing Training International has developed a wiring training course to meet the expected FAR requirements. The program enables the operator or repair station to tailor the curriculum to the technical expertise of the student and to the specific airplane model.

Airplane Wiring Systems Training

Airplane Wiring Systems Training

AIRPLANE WIRING SYSTEMS TRAINING

In a report to the U.S. Federal Aviation Administration (FAA) in January 2001, the Aging Transport System Rulemaking Advisory Committee recommended that wiring training be a significant component of future maintenance procedures for airplane wiring systems. FlightSafety Boeing Training International (FSBTI) offers an FAA-approved training course in Boeing airplane wiring systems that is tailored to airplane and avionic technicians, engineering staff, and other personnel with access to the airplane.

The course, Airplane Wiring Systems, incorporates lecture, discussion, and demonstration to teach students how to inspect the condition of the airplane wiring properly, use the Boeing Standard Wiring Practices Manual, implement standard wire and connector repairs, understand and apply the processes and procedures in the Wiring Diagrams Manual, and apply standard wire system troubleshooting procedures. The seven-module curriculum meets Air Transport Association Level IV standards for the development of training materials to be used by airlines in training airplane maintenance personnel.

For further information, contact FSBTI by e-mail at trainingrequests@fsbti.com or by mail at P.O. Box 34787, Seattle, WA 98124-1787, USA. Course schedules, locations, and dates are available on the FlightSafety Boeing web site on the World Wide Web at http://www.fsbti.com/.

-

Boeing is revising the Boeing Standard Wiring Practices Manual to add new procedures for cleaning installed wiring, performing a detailed wiring inspection, and protecting wiring during related and unrelated maintenance.

-

In addition to the requirements outlined in the regulatory mandate and the guidance provided by the ACs, Boeing will be available to assist operators in the development and implementation of their enhanced continued airworthiness programs. For example, Boeing will release supplemental guidance material that, although not expected to be regulatory agency approved, will provide information on existing maintenance, training, and inspection programs that are known to have complied with the SFAR. This guidance material also will describe regulatory programs or material not typically distributed worldwide. Operators can use this information to develop their programs.

SummaryThe FAA asked industry representatives to review the systems installed on the aging airplane fleet and determine whether changes to existing processes and designs were needed to offset the effects of aging. Investigation of airplane wiring systems indicated that, although no endemic issues related to the immediate safety of the airplanes were identified, safety enhancements could be implemented. These enhancements relate to the design and maintenance of airplane electrical systems and associated documentation and training. The FAA has developed a program, the EAPAS, to promote voluntary incorporation of these enhancements, charter related reporting and research projects, and provide guidance on the expedited incorporation of the anticipated changes to related federal regulations. Boeing is actively participating in the EAPAS and is providing the industry with information and entire programs that are expected to comply with the forthcoming changes. In addition, Boeing will assist operators in their efforts to incorporate these changes into their current maintenance and training programs. |

DONALD ANDERSEN

MANAGER

REGULATORY AND INDUSTRY LIAISON

BOEING COMMERCIAL AIRPLANES

PAUL LAPWOOD

INSTRUCTOR

MAINTENANCE

FLIGHTSAFETY BOEING TRAINING INTERNATIONAL

GIL PALAFOX

MANAGER

MAINTENANCE ENGINEERING

BOEING COMMERCIAL AIRPLANES

| Top of page | Boeing Home | Boeing Commercial | Contact Aero |

Aero Copyright © The Boeing Company. All rights reserved.