Published: July 2003

Preventable accidents and incidents related to erroneous flight instrument information continue to occur despite improvements in system reliability, redundancy, and technology. In particular, modern flight instruments provide more information to the flight crew with greater precision. Flight crews seldom are confronted with instrument problems; however, when these problems do occur, their rarity can make the situation worse.

To overcome the potential problems associated with infrequent failures, flight crews should be aware of the piloting techniques summarised in this article, follow the guidance described in operations and training manuals, and comply with airline training when facing a flight instrument anomaly.

Reviewing the following important information can help flight crews make the proper decisions when encountering erroneous flight instrument indications:

- Recent erroneous flight instrument incidents.

- Pitot and static instrument system design.

- Recognition and recovery techniques.

- Procedures to assist flight crews.

1. RECENT ERRONEOUS FLIGHT INSTRUMENT INCIDENTS

Controlling modern airplanes generally is a routine task in normal and most non-normal situations. In this era of aural, visual, and tactile warnings and advanced instrumentation, flight crews consistently are alerted when certain airplane parameters are exceeded. However, flight crews must react properly when confronted with instrument failure, which can cause a significant loss of information. Unfortunately, incidents and accidents have occurred where flight crews have had difficulty with erroneous flight instrument indications.

A previous Aero article, “Erroneous Flight Instrument Information” (Aero no. 8, Oct. 1999), reviewed four accidents and incidents. During the three recent incidents described here, flight crews were faced with uncertainties about flight instrumentation.

-

Incident A — Plugged Pitot Probes

An airplane took off with the left and right pitot probes plugged by insect activity. Primary airspeed indications were inactive during the takeoff roll, but standby airspeed was normal. The flight crew noticed the condition at an airspeed assumed to be greater than 80 kias and elected to continue the takeoff.The captain’s airspeed recovered at an altitude between 1,000 and 2,000 ft; the first officer’s indicated airspeed remained at 30 kias. The crew performed an air turn-back and a normal landing. The airplane had been on the ground for 36 hr before the event. The pitot probe blockage had not been detected during the walk-around conducted by the flight crew.

There have been several in-service reports of insects such as mud-dauber wasps sealing pitot probes. These events raise concern about the potential for a takeoff with erroneous airspeed indications and the possibility of inappropriate crew action, which could lead to a high-speed rejected takeoff or loss of situational awareness in flight.

-

Incident B — Open Static Port Drains

An airplane departed without the static port drain caps, which had been removed during maintenance but not replaced. As a result, the static lines were open to cabin pressure. There was significant airframe vibration after takeoff. The flight crew deduced that the airspeed indicators were under-reading and observed that the altimeter was not changing. They declared an emergency and returned without incident. After the flight, maintenance discovered that the flaps had been damaged by excess speed. -

Incident C — Partially Blocked Pitot Tube

An airplane departed with the captain’s pitot tube partially obstructed by insects. The captain’s airspeed indication lagged behind the first officer’s airspeed indication. The first officer was conducting the takeoff, and by the time the late callouts and erroneous indications were identified, the crew decided to continue the takeoff.During climbout, several engine indicating and crew alerting system (EICAS) messages were noted, which later disappeared. Airspeed indications appeared to be normal. Upon reaching cruise altitude, the captain’s airspeed indicated higher than the first officer’s indication but seemed reasonable.

When the first officer started a step climb, the autopilot attempted to reduce speed by pitching up. The vertical navigation function had used the captain’s erroneous air data information for the climb and tried to reduce the apparent overspeed. This resulted in an approach to stall warning (stick shaker) and subsequent significant loss of altitude during the recovery. The crew then diverted to an uneventful landing.

Partial pitot probe or static port blockages can present challenges to the flight crew. Knowledge of potential problems and system design aids flight crews in successfully handling these types of problems.

2. PITOT AND STATIC INSTRUMENT SYSTEM DESIGN

Good system design and redundancy have made the rate of instrument and system anomalies very low compared with the number of departures.

On early commercial airplanes, pitot and static information was fed directly to the airspeed indicators, and static information was indicated on the altimeter. The only electrical power required was for instrument lighting.

Later designs replaced pneumatic airspeed indicators and altimeters with servo-pneumatic types. Airspeed information could be displayed either in the central air data computer (CADC) mode or all-pneumatic (backup) mode. The CADCs added compensation for errors and were a significant advance. Eventually, the technology was developed to the point that electric air data instruments were driven only by CADCs, and only the new standby airspeed and altitude indicators were pneumatic.

With the advent of the glass cockpit, air data instruments remained a round-dial, all-electric design, but they received information from digital air data computers through digital data buses. This use of digital information eventually made it possible to display the airspeed and altitude tapes. Standby instruments essentially were unchanged.

The most modern systems today use an air data inertial reference unit (ADIRU), which incorporates the best information from three pitot and static sources and provides a single set of data to both pilots. An ADIRU receives information from air data modules, which are located close to the pressure sources. A secondary attitude air data reference unit is available as a backup. Dedicated standby air data modules provide data to the standby instruments.

Throughout this design improvement process, the reliability and integrity of air data systems have improved greatly, even with the increased number of system functions and interactions. Pitot probes and static ports remain critical sources of data for flight deck instruments.

3. RECOGNITION AND RECOVERY TECHNIQUES

Typically, the crew recognises problems during takeoff or shortly after liftoff. However, incidents and accidents have occurred in flight, primarily because of icing and its effects. Problems during takeoff most often are caused by plugged pitot probes or static ports.

When a pitot probe is completely plugged, the airspeed indication remains pegged at its lower stop during the takeoff roll. The crew has only a short time during the takeoff roll to recognise erroneous airspeed indications. For example, at maximum takeoff thrust, a 777-200 can accelerate from 30 to 80 kt in 9 to 12 sec, depending on gross weight. If the flight crew does not reject the takeoff, the indicated airspeed will start to increase immediately after liftoff.

As the airplane climbs, indicated airspeed continues to increase through the correct value. The altimeter operates almost correctly during the climb. Eventually, the indicated airspeed can exceed VMO, in which case the overspeed warning occurs. Trusting the erroneous airspeed indicator can be tempting when it appears to begin operating normally. However, the pilot should not increase pitch or reduce thrust or both to respond to erroneous airspeed indications of this type.

When static ports are completely plugged, there is no apparent indication during the takeoff roll. After liftoff, at a constant actual speed, the airspeed indications decay rapidly, reaching the lower end indication. The altimeter remains at the field elevation (assuming the trapped static pressure is that of the field elevation). If the crew relies on the faulty airspeed indicator for information, the typical response would be to lower pitch attitude, possibly causing airspeed limitations to be exceeded.

Total blockages of the pitot or static systems are rare. However, many anomalies are associated with partial blockages, damage, or deterioration of system parts. Anomalies can result when

- Pitot probe covers or static port covers are not removed.

- Pitot or static hoses are disconnected.

- Hoses are leaking.

- Water trapped in the lines freezes during flight.

- Pitot probes or static ports are blocked by volcanic ash.

- The radome is damaged.

- Icing occurs on the pitot probes or static ports.

- Pitot probes or static ports are blocked by insects.

- Pitot probes or static ports are physically damaged.

- Air data pressure sensors fail.

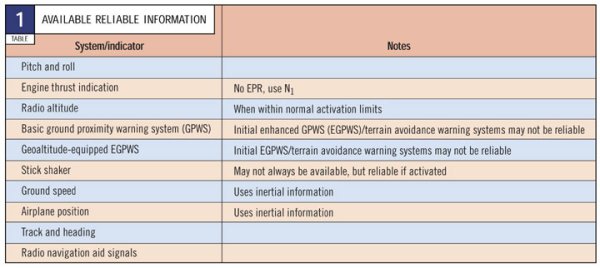

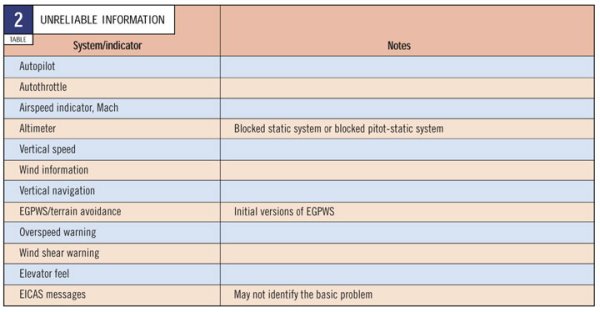

Sometimes a partially blocked pitot port (e.g., incidents A and C) presents more of a problem than a completely blocked pitot port. Situations where static ports are partially blocked or open to cabin pressure can be equally difficult (e.g., incident B). A key aspect in recovering successfully is identifying which instruments are accurate. Tables 1 and 2 list which flight deck instrument information is and is not reliable during pitot or static system anomalies.

The following basic actions are essential to a successful recovery from these problems. Flight crews should

- Recognise an unusual or suspect indication.

-

- Monitor airspeed indications.

- Advise other crew-members immediately about flight instrument indications that do not agree with the flight conditions.

- Confirm by crosschecking other instruments,

including standby instruments.

- Maintain control of the airplane with basic pitch and power skills.

-

- Establish a pitch attitude and power setting that are appropriate to the situation.

- Allow sufficient time for problem solving.

- Take an inventory of reliable information.

-

- Compare pitch and power indications with settings recommended for the phase of flight.

- Consider items in tables 1 and 2 to determine reliability.

- Find and/or maintain favourable flying conditions, such as daylight visual conditions.

- Obtain assistance from others.

-

- Air traffic control can help with position and ground speed.

- Be aware that air traffic control communication of transponder information could be erroneous.

- Use checklists.

-

- Do not trust previously suspected instruments, even if they appear to be operating correctly.

- Review unreliable airspeed or other appropriate checklists.

4. PROCEDURES TO ASSIST FLIGHT CREWS

Procedures are available to assist flight crews encountering erroneous flight instrument indications. Recent changes in procedures provide guidance on monitoring airspeed indications during the takeoff roll.

During flight, the airspeed unreliable non-normal procedure provides important information. This checklist helps the crew recognise evidence of unreliable airspeed-Mach indications and provides recall steps to emphasise the importance of checking attitude instruments and thrust levels first. The IAS DISAGREE and ALT DISAGREE messages make recognition of anomalies easier. Delay in recognising a problem and taking corrective action could result in loss of airplane control.

Flight crews should be aware of the approximate airplane attitude and thrust for each flight manoeuvre. Knowledge of airplane pitch attitudes for given flight conditions and configurations can help identify potential airspeed anomalies before they degrade to an unsafe condition. Checklists can direct flight crews to reliable data sources and provide key guidelines, such as directing crews to:

- Maintain visual conditions.

- Establish landing configuration early.

- Use electronic and visual glideslope indicators, where available, for approach and landing.

- Use various sources, such as the navigation display, to determine ground speed and wind effects.

SummaryErroneous flight instrument indications caused by pitot and static system anomalies can confuse an unprepared flight crew. A crew’s failure to respond correctly can result in an airplane accident or incident. With knowledge of pitot and static systems, an understanding of the types of erroneous flight instrument indications that can occur, and the mindset to fly the approximate pitch and power, the flight crew can establish and maintain the airplane in a safe condition. The crew can determine which instruments are reliable and develop a strategy for recovery by following basic airmanship and checklist guidance to land the airplane safely. |

DAVID CARBAUGH

CHIEF PILOT

FLIGHT OPERATIONS SAFETY

BOEING COMMERCIAL AIRPLANES

| Top of page | Boeing Home | Boeing Commercial | Contact Aero |

Aero Copyright © 2003 The Boeing Company. All rights reserved.