Landing Gear - Tyre Serviceability

The following data has been extracted from the Goodyear Aircraft Tire Care and Maintenance Manual and is provided for information only.

image source: http://www.saywell.co.uk/pages/goodyearfr.htm

General Inspection and Removal Criteria

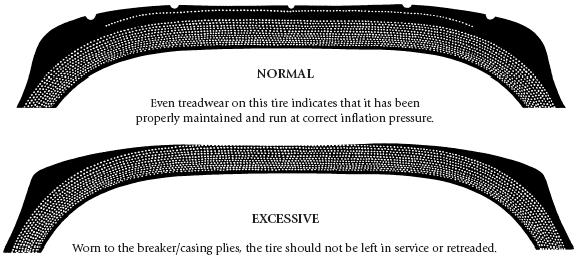

Treadwear

Inspect treads visually and check remaining tread. Tyres should be removed when tread has worn to the base of any groove at any spot, or to a minimum depth as specified in aircraft Type Orders.

Return To Base Limits

Goodyear tyres can remain in service with visible cord in the tread area only as long as the top fabric layer is not worn through or exposed for more than 1/8 of the circumference of the tyre, and not more than one inch wide. Tyres within these limits can continue in service no longer than necessary to return to a maintenance base and be replaced. For all other circumstances, normal removal criteria are still recommended as per the rest of this manual.

Note: Further use of tyres beyond this point may render a tyre unsafe or un-retreadable.

Uneven Wear

If tread wear is excessive on one side, the tyre can be demounted and turned around, providing there is no exposed fabric.

Tread Cuts

Inspect tread for cuts and other foreign object damage and mark with crayon or chalk. Follow the removal criteria below:

Follow specific cut removal criteria from Aircraft Maintenance manuals, Operation manuals, or tyre cut limits on the tyre sidewall when available.

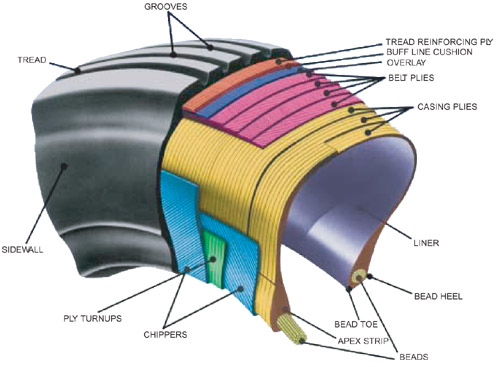

When specific cut removal criteria are not available use the following Goodyear removal criteria: any cut into the casing plies on bias tyres, any cut into the belt package on radial tyres, any cut which extends across one or more rubber tread ribs to the fabric, rib undercutting at the base of any cut.

Warning: Do not probe cracks, cuts or embedded foreign objects while tyre is inflated.

Sidewall Damage

Remove tyre from service if weather-checking, cracking, cuts and snags extend down to the casing ply in the sidewall and bead areas. Cuts and cracks deeper than one ply require the tyre to be scrapped.

Bulges

Bulges in any part of tyre tread, sidewall or bead area indicate a separation or damaged tyre. Mark with crayon and remove from service immediately.

Fabric Fraying/Groove Cracking

Tyres should be removed from service if groove cracking exposes fabric or if cracking undercuts tread ribs.

Flat Spots

Generally speaking, tyres need not be removed because of flat spots due to touchdown and breaking or hydroplaning skids unless fabric is exposed.

Casing Flat Spotting

Loaded tyres that are left stationary for any length of time can develop temporary flat spots. The degree of this flat spotting depends upon the load, tyre deflection and temperature. Flat spotting is more severe and more difficult to work out during cold weather. Under normal conditions, a flat spot will disappear by the end of the taxi run.

Radial Tyre Sidewall Indentation

Remove from service with 3mm or greater sidewall indentation.

Beads

Inspect bead areas next to wheel flanges for damage due to excessive heat, especially if brake drag or severe braking has been reported during taxi, take-off or landing. If damaged, remove tyre from service.

Tyre Clearance

Look for marks on tyres, gear, and in wheel wells that might indicate rubbing due to inadequate clearance.

Wheels

Check wheels for damage. Wheels that are cracked or damaged should be taken out of service for repair or replacement in accordance with manufacturer's instructions.

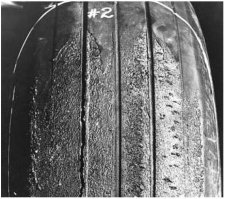

Typical Treadwear

Cuts

Penetration by a foreign object on runways and ramps. Remove from aircraft if injury extends into fabric. |

Spiral Wrap

Some retreads have reinforcing cords wound into the tread which become visible as the tyre wears. This is an acceptable condition and not cause for removal. The wrap reduces chevron cutting and tread chunking. |

Tread Chunking

A condition in the wearing portion of tread usually due to rough or unimproved runways. Remove if fabric is visible. |

Tread Separation

A separation or void between components in the tread area due to loss of adhesion, usually caused by excessive loads or flex heating from under-inflation. Remove immediately. |

Open Tread Splice

A crack in the tread rubber where the joint (splice) separates in a radial (sideways) direction. Tyres with this defect should be removed from service. |

Chevron Cutting

Tread damage caused by running and/or braking on cross-grooved runways. Remove if chunking to fabric occurs or tread cut removal criteria are exceeded. |

Peeled Rib

Usually begins with a cut in tread, resulting in a circumferential delamination of a tread rib, partially or totally, to tread reinforcing ply. Remove from aircraft. |

Thrown Tread

Partial or complete loss of tread down to tread fabric ply or casing plies. Remove from aircraft. |

Skid

An oval-shaped flat spot or skid burn in the tread rubber. May extend to or into fabric plies. Remove if balance is affected, fabric is exposed, or tyre is ruptured. |

Rubber Reversion

An oval-shaped area in the tread similar to a skid, but where rubber shows burning due to hydroplaning during landing usually caused by wet or ice-covered runways. Remove if balance is affected. |

Groove Cracking

A circumferential cracking at the base of a tread groove; remove if fabric is visible. Can result from under-inflated or overloaded operation, or improper storage conditions. |

Rib Undercutting

An extension of groove cracking progressing under a tread rib; remove from aircraft. Can lead to tread chunking, peeled rib or thrown tread. |